A while ago I received a nice email from Tony Souza regarding construction issues with a new dory he intended building for the old Portuguese barkentine

Gazela Primeiro.Hello Ross,

Thanks for your recent article "Stems and Trailers". In that article you discuss natural timber vs plywood construction and show the merits of plywood glued lapstrake for boats that are dry stored.

Im trying to choose a construction technique to use for a reproduction dory that will be "dry sailed". The dory is a Grand Banks dory of 17 feet overall, 13 feet on the floor. The new dory has to resemble closely the last of the three dozen Portuguese grand banks dories that sat on the deck of Gazela Primeiro, the 100+ year old Portuguese barkentine on which I am one of the all volunteer crew. Last winter we patched and repaired the last dory, and this year Id like to build a dory to be used often for the teaching of boat handling, rowing, and dory sailing. the boat handling includes launching and retrieving over the side using hand operated boatfalls. The new dory will spend most of its time stacked inside the old dory, the two as deck displays of what was used in long line fishing of the early 20th century.

As a matter of resemblance the new dory will have four frame sisters overlapped, removable thwarts, 5/8" cedar planking, solid gunwales, a mast step on the floor and two sets of oarlocks.

For ease of construction and in keeping with the dry storage idea I plan on using modern materials where I can. The flat bottom will be Meranti plywood already on hand, no need to soak the floor seams closed before putting boat into the water. The frames are already built from laminated ash. Tree crotch and buttress sections are too difficult to find. I plan to epoxy the garboard plank to the bottom, glass tape and epoxy the inside seam. After planking I plan to turn the boat over and glass the bottom and garboard with cloth.

After that long prologue we come to my uncertainty area, the clinker planking joints. Its tempting to use lap-stitch aka ship lap joints, easily cut with a router and epoxy fastened. On natural, i.e. not plywood, timber that may lead to splitting along the grain at the join. Likewise dory lapped (rolling bevel) joints likewise glued might suffer splitting. I should have said earlier that using modern glues and eliminating metal fastners is a goal. The old dory is a pincushion of steel nails on the planking joints which has resulted in rusty streaks and rotten wood. (Of course dories were not supposed to last more than a couple years in ocean service. Old dory is probably 40+ years old.)

Would it be better to caulk the planking seams with Boat Life, a polysulfide, rather than epoxy fasten? The frames are there to give cross grain strength. With your expeience you might see that Im headed for problems not yet envisioned.

Any suggestions will be very welcome and gratefully accepted.

Gazela can be seen at www.gazela.org.

A picture of the old dory is attached. Here is part of the text of my reply: -

I agree totally with your concerns regarding "hard" gluing of either "lapstitch" or dory-lap joints when using natural timber rather than plywood - I believe that they would definitely crack at the point where the planking thickness returned to single-plank. Harry Bryan wrote about the matter when he did a couple of articles for WoodebBoat Magazine about the building of his Daisy design. She had either double-planked cedar (glued with epoxy) for the bottom, or a single sheet of plywood. The topsides were planked with lapstrake cedar planks in the normal manner (I think using copper clench nailing from memory). The important thing in our context is that he expected her to be dry-sailed, and after completing the planking in the normal way, he dragged a sharp, flat-blade screw driver along the underside of the lap on the outer side of the planking. This produced a sort of square-shaped groove of about 1/8" x 1/8" in the underside of the lap. He then filled the groove with a bead of polyurethane (I would use 3M 5200 or Sikaflex 292, using a polyurethane-specific primer)

Having said all that, I wonder whether you could just glue the entire lap with polyurethane (I dont know enough about polysulfide to say anything about its adhesive qualities where no fastenings are used). The polyurethane is strong enough, but I dont know whether a fully-glued lap would allow enough movement to overcome the cracking problem, even given the flexibility of the compound - but my guess is that it would be ok, especially if the glue-line was thick.

If I was doing it, Id go the copper-fastened route, with the polyurethane (or polysulphide) run into the groove under the lap.

I think that the garboard arrangement you propose would be fine. The glass on the outer face should supply cross-grain reinforcement, and the tape on the inside will extend some distance beyond the vulnerable line of intersection between the inside faces of the bottom and the garboard.

On two boats I built (one of which ended up in the Jody Foster film,

Nims Island - see the recent comment made on Duckworks http://www.duckworksmagazine.com/10/reports/may/index.htm ), I made the bottom from Western Red Cedar glued strip, continuing around the turn of bilge, after which I continued the planking as plywood glued lapstrake. I cut the bevel on the bottom planking to accept the first lapstrake plank before glassing the bottom. When glassing the bottom, I continued the glass right around and onto the bevelled face. This meant that when the first plywood plank was glued on, the glass was sandwiched between the WRC strip planking and the inner face of the plywood - the aim being to prevent splitting in the WRC. This explanation is a bit clumsy, but I havent got time right now to do a sketch. In your case this will not be necessary, as you will have the glass on the outside of the cedar planking anyway.

??

|

| Western Red Cedar bottom planking |

???

|

| Bottom covered with 400gsm (12oz) double-bias glass and the first two planks of plywood lapstrake attached - the first plank going over the glass, which itself had been laid over the bevelled edge of the cedar bottom planking. |

???Here is Tonys latest up-date: -

Hiya Ross,

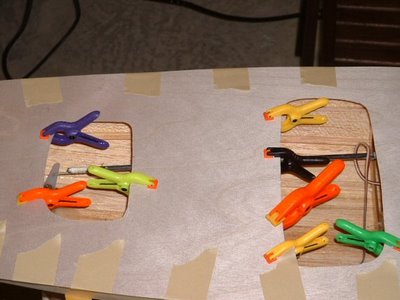

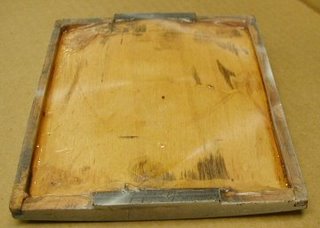

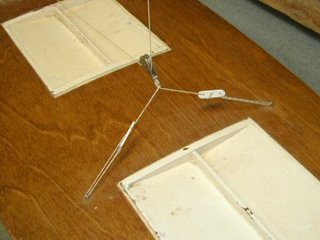

Here are three pix of the dory project to date. This boat is a copy of the last original belonging to Portuguese fishing barkentine Gazela Primeiro. You can see more pictures on www.Gazela.org and my facebook page. My version of the dory has a meranti plywood bottom and white cedar planking over laminated ash frames. The gunwale and cap are white oak. The dory will essentially be dry sailed i.e. living on Gazelas deck most of the time and occasionally be used for crew training and exhibition at home and ports of call.

After corresponding with you some time ago I took your advice and epoxy joined only the garboard plank to the bottom. The rest of the construction has followed traditional methods. The upper edge of the garboard and the remaining planks are dory lapped and copper riveted. Planks to frames are joined with Si bronze screws.

I think we talked about covering the bottom and up to the upper edge of the garboard with synthetic cloth and epoxy.

Now areas where I could use advice:

What cloth would be appropriate? I dont think the dory will ever see a beach, but it might. So a light cloth should do.

Is there an advantage to graphite additive to the epoxy?

Any tricks to applying the cloth?

Thanks for your help,

Tony Souza

Dear Tony,

Thanks very much indeed for the up-date, and for the nice photos. The boat looks super to my eyes, and Id love to take her out in the rough stuff - preferrebly with some weight in the bottom to represent the ballasting effect of a load of Cod!

My appologies for the delayed reply - we have been recovering from the devastating flash-flood which wiped us out on January 10, and priorities tend to be re-arranged!

For the cloth, the simplest would be 200gsm (6oz) woven glass. This is light and easy to use, and gives a good level of protection, and more importantly, provides a sort of screed to ensure an even thickness of epoxy. Dynel is also a good option (4oz, I think, but you would need to check with the supplier). Dynel is bulkier than glass for the same weight, and it has superior abrasion resistance - I like it on decks - but it doesnt have the tensile stiffness of glass so it will have less structural effect on the garboard-to-bottom joint. For a hefty boat like yours which may get handled roughly, Id give serious thought to using 400gsm (12oz) double-bias glass cloth. It isnt woven, so it takes bends fairly well, and with the fibres aligned 45 degrees/45 degrees, every fibre crosses the longitudinal joints. It is cheaper than woven glass, but is heavier than the normal 6oz stuff.

I normally use the dry application method (for weights up to 12oz). I lay the cloth over the dry, sanded, and vacuumed surface, and them smooth it into position with a dustpan brush or a wide, dry paintbrush. Tape any troublesome edges down with temporary bits of masking tape. Then start by mixing small quantities of epoxy and pour them onto the glass (or Dynel) and spread them with a squeegee - I use rectangles of 1/16" model aircraft balsa as they can be bent along the grain if required, and the corners dont snag on the glass. Dont press too hard, as you will end up aerating the epoxy and making it go creamy with minute air bubbles (just like what happens when whipping cream). Just use a gentle figure-eight sweeping motion to get it out onto the surface. Dont fuss about getting it to wet-out - that will happen automatically. Keep on mixing, pouring and spreading until the entire surface is covered. Small batches are good, as they dont heat up so rapidly in the container.

When the surface is covered, use disposable brushes and/or disposable foam rollers with about a 1/8" nap to distribute the resin evenly. I use dry brushes and rollers - they pick-up from the excessivcely wet areas and put down in the dry areas. When all is even, use the squeegees again (held at about 45 degrees to the surface) to scrape off excess resin so you end up with just the wet cloth, but no visible pooling of liquid resin.

After the epoxy has gone off enough to be certain that the cloth wont float up off the surface - this depends on temperature and rate of cure - but when it gets to a "green"state of cure, lay on several more coats of epoxy to fill the weave so that when you finally sand the surface (after removing any amine blush with water and cloths, sponges or Scotchbrite pads) you are only sanding epoxy and not going through to the glass.

Have a look on my website under the button labelled "First Mate Photos 3" for a brief pictorial demonstration - the thumbnails enlarge if you click on them.

French artist Julien Berthier created this boat. According to him, "Love love is the permanent and mobile image of a wrecked ship that has become a functional and safe leisure object".

French artist Julien Berthier created this boat. According to him, "Love love is the permanent and mobile image of a wrecked ship that has become a functional and safe leisure object".